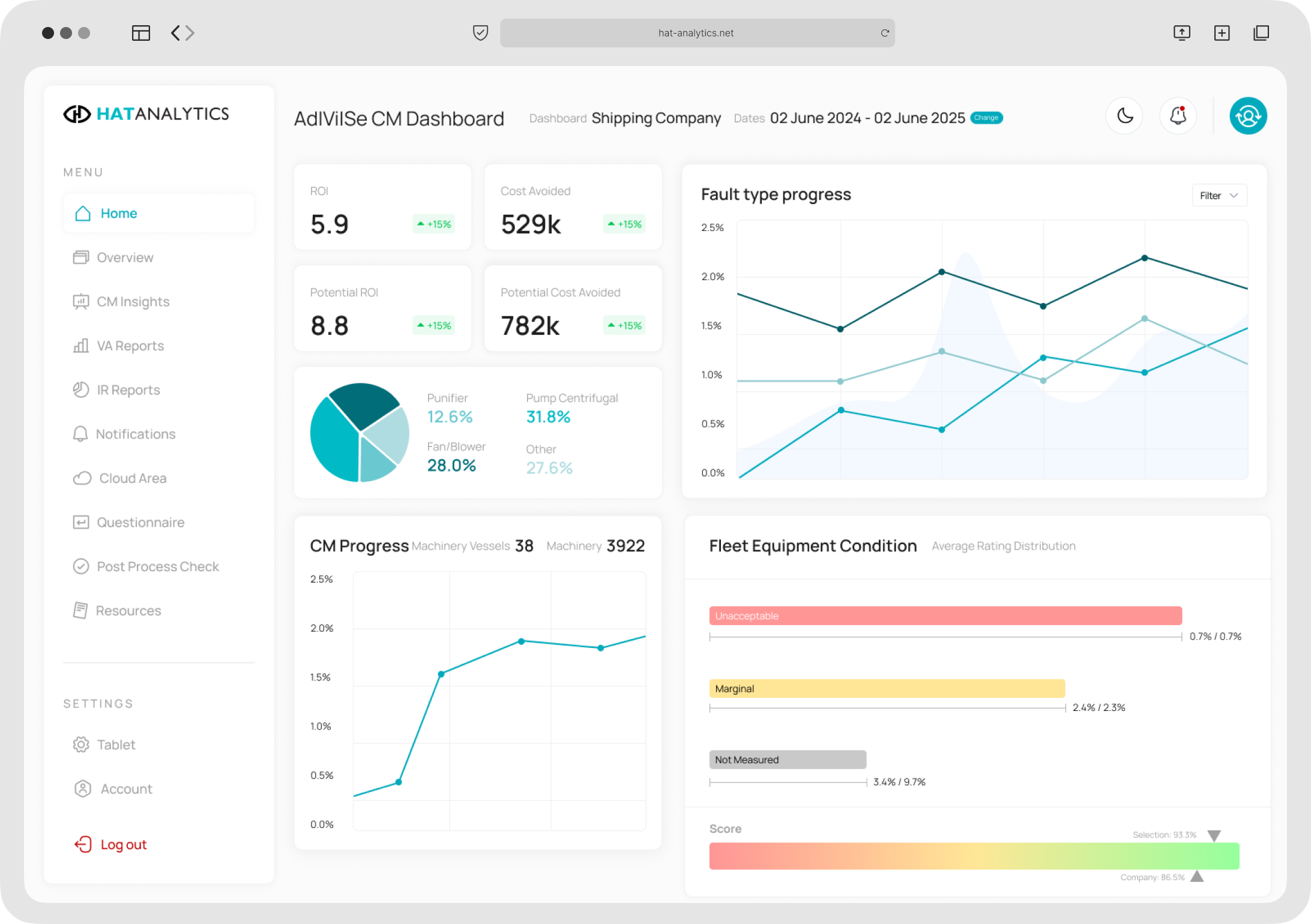

Technology & Innovation

Bow Thruster - Unacceptable

H.F.O. Purifier No. 1 - Marginal

Smart Maritime Diagnostics

H.F.O Purifier No. 1

Excessive vibration on purifier bowl. Indication of mass unbalance from sludge deposits. Immediate bowl cleaning is recommended.

Bow Thruster

Elevated bearing temperature with irregular vibration. Indication of insufficient lubrication and early-stage wear. Prompt lubrication and inspection are recommended.

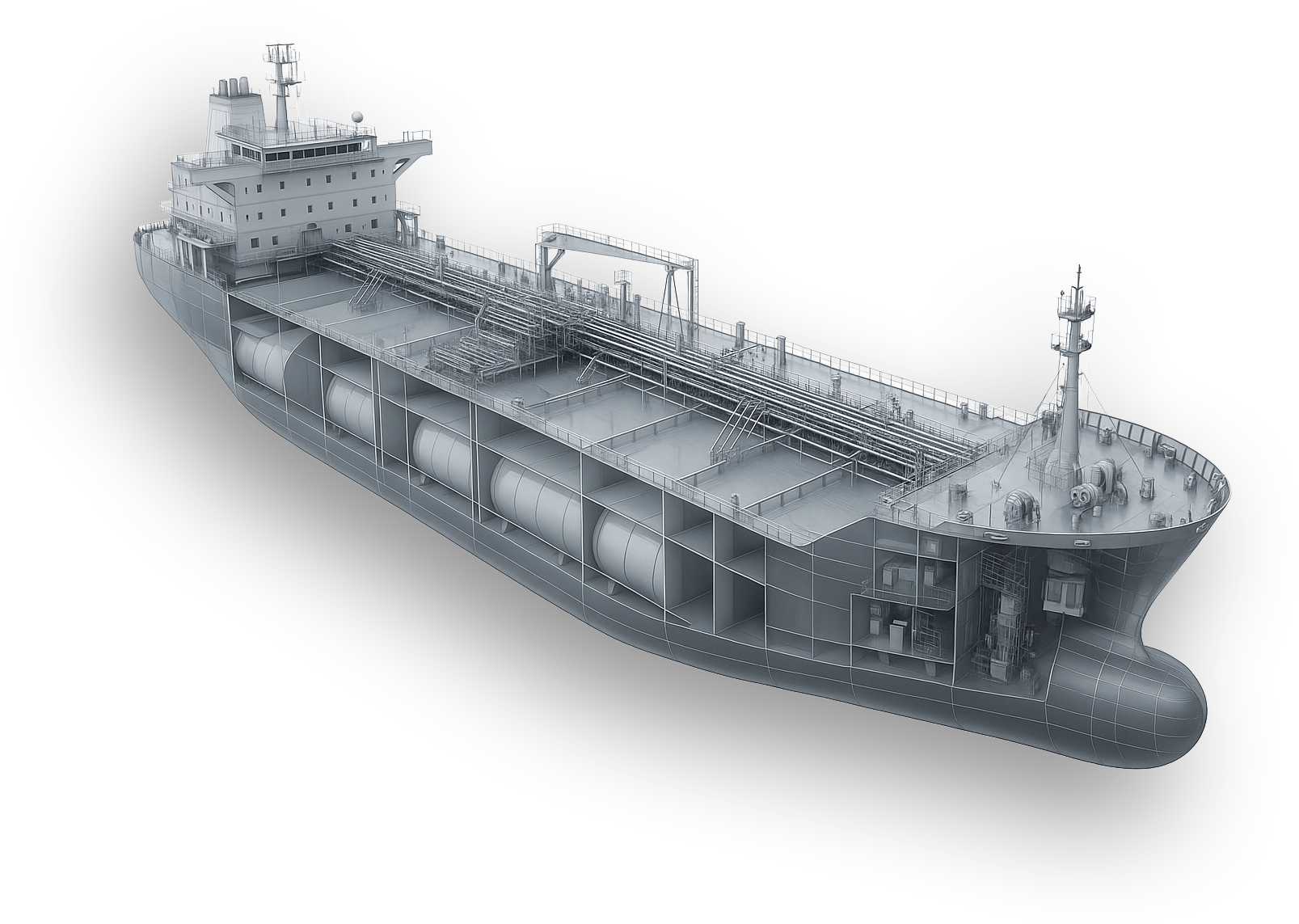

Smart Solutions For Smarter Fleets

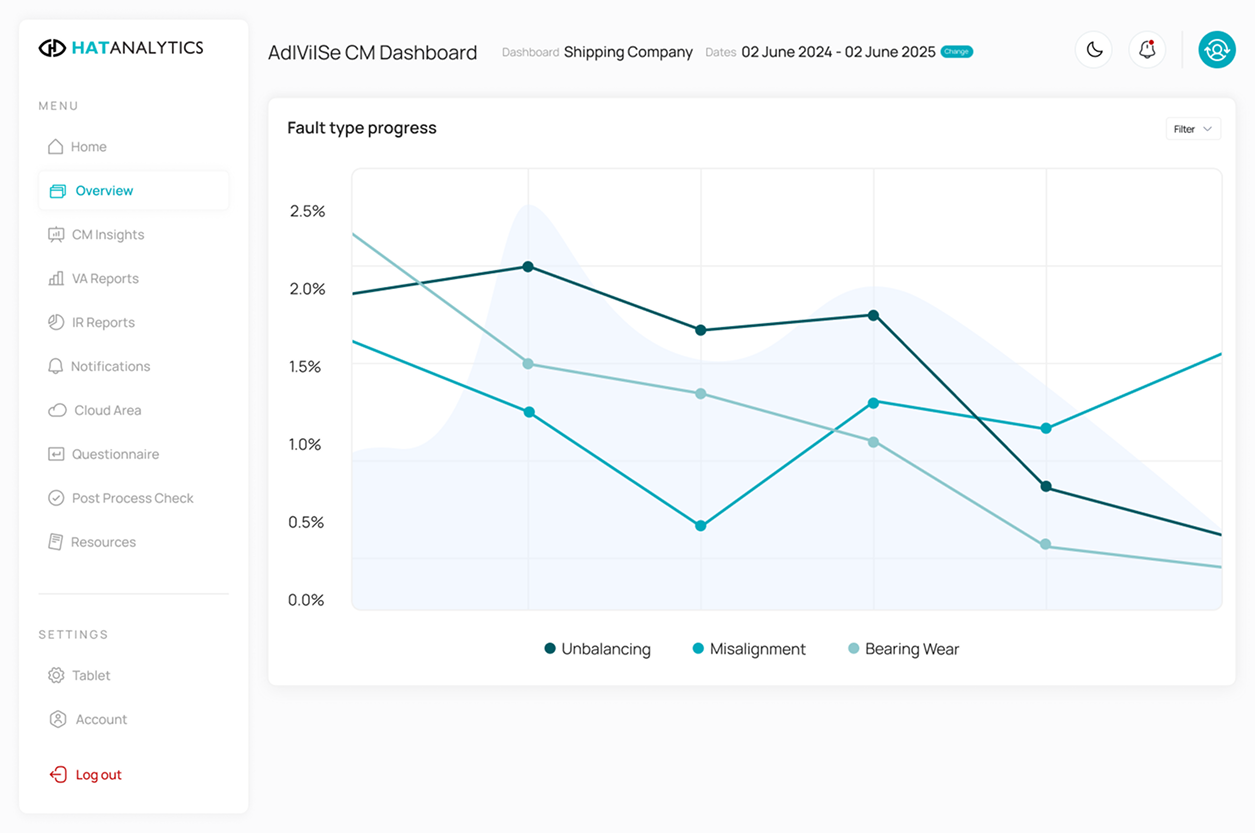

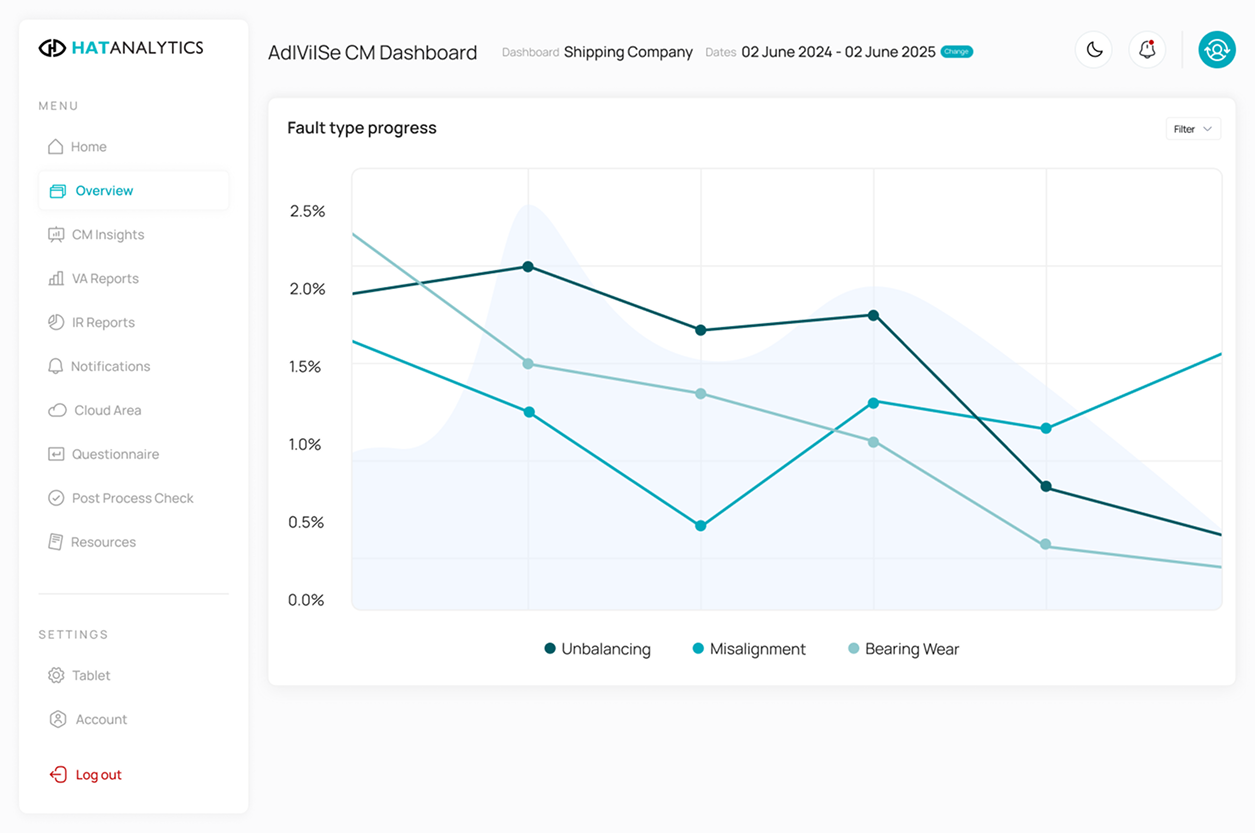

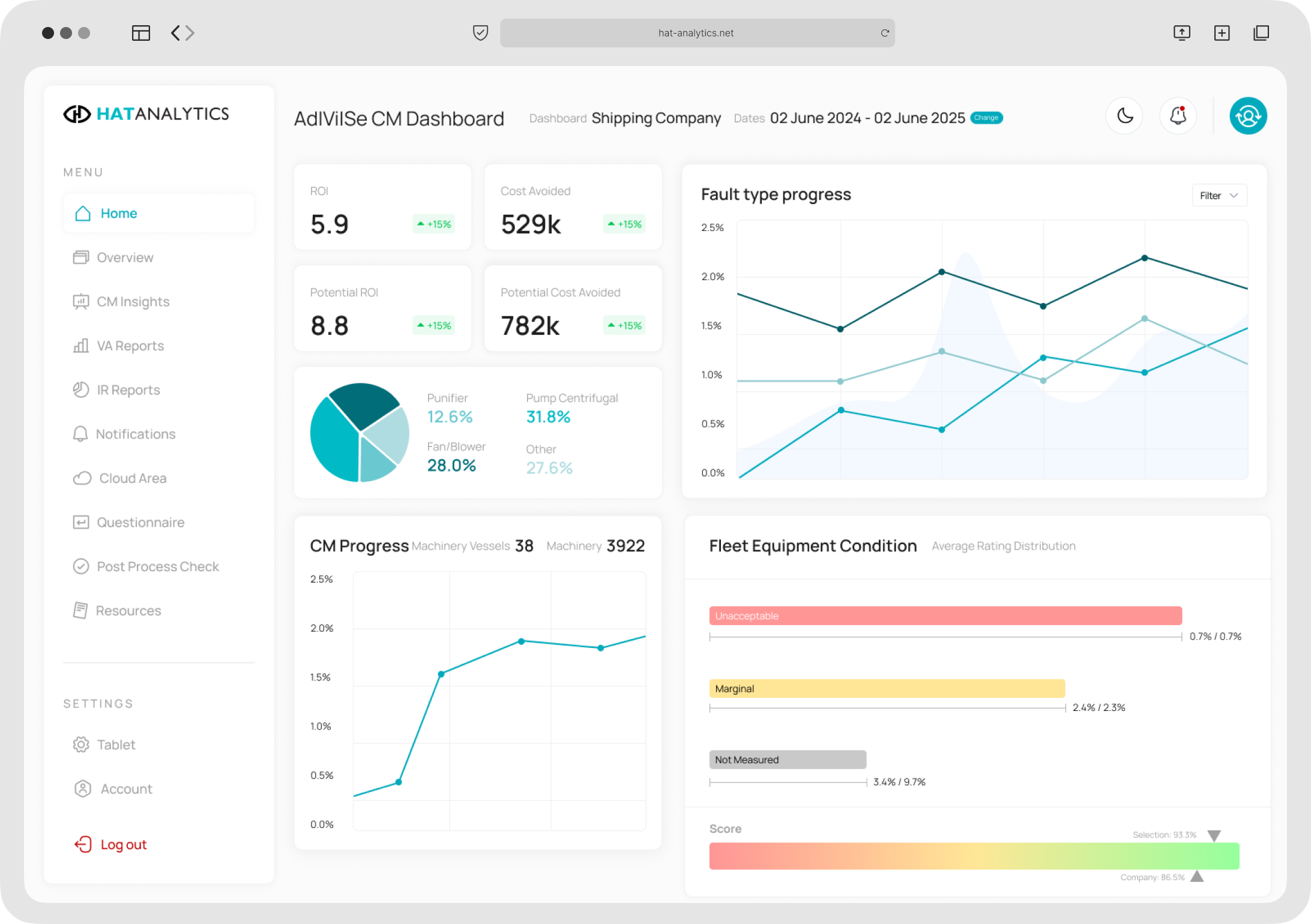

Adaptive Diagnostics with AdInsights

At the core of HAT Analytics is AdInsights, our continuously learning diagnostics engine.

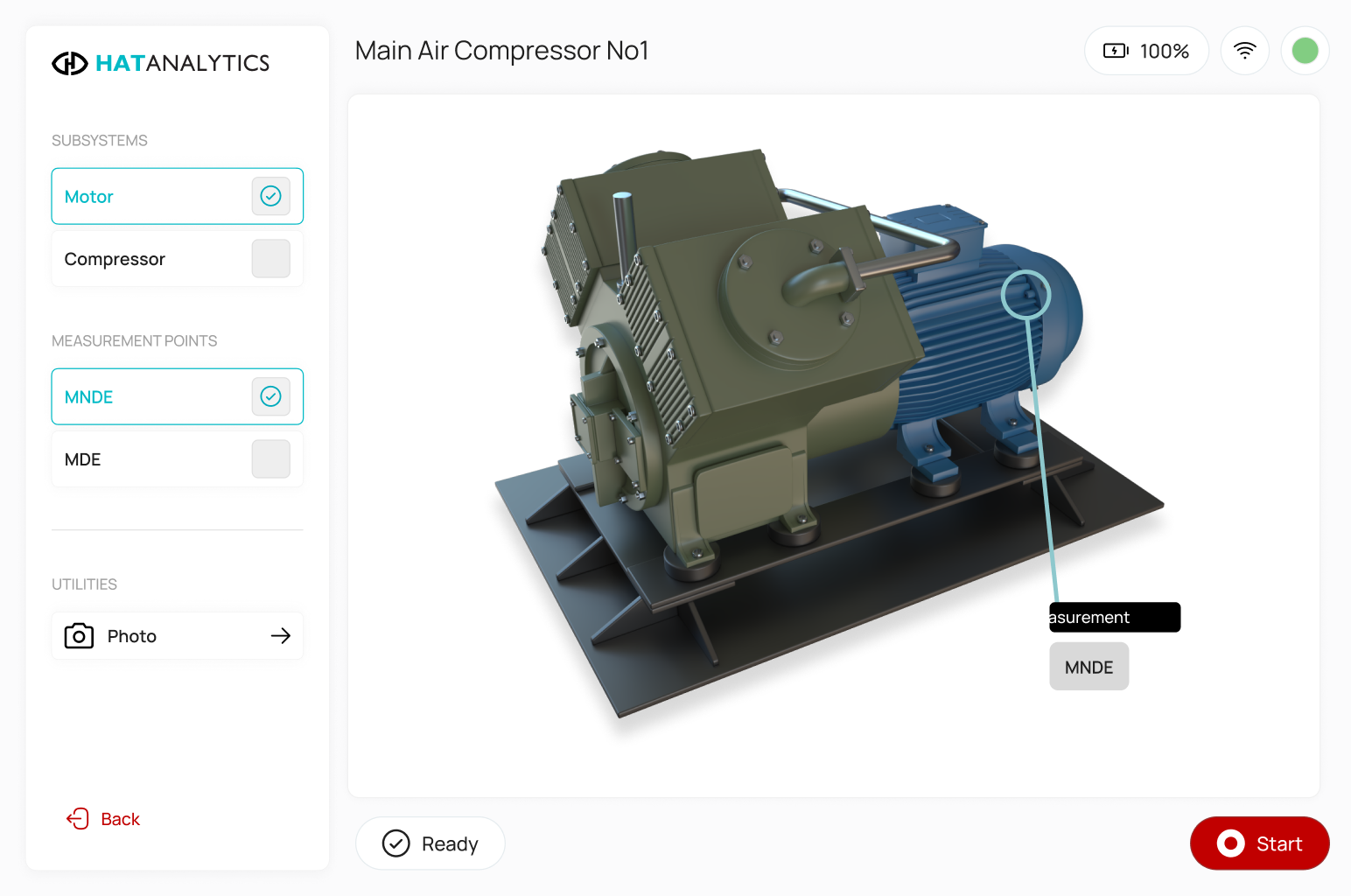

Edge Intelligence, Built In

AdViSe systems perform diagnostics directly at the point of measurement.

Precision Sensors, Maritime-Ready

From our in-house sensors to partner-sourced models, every unit is built for the marine environment.

Adaptive Diagnostics with AdInsights

At the core of HAT Analytics is AdInsights, our continuously learning diagnostics engine.

Precision Sensors, Maritime-Ready

From our in-house sensors to partner-sourced models, every unit is built for the marine environment.

Edge Intelligence, Built In

AdViSe systems perform diagnostics directly at the point of measurement.

Precision Sensors, Maritime-Ready

From our in-house sensors to partner-sourced models, every unit is built for the marine environment.

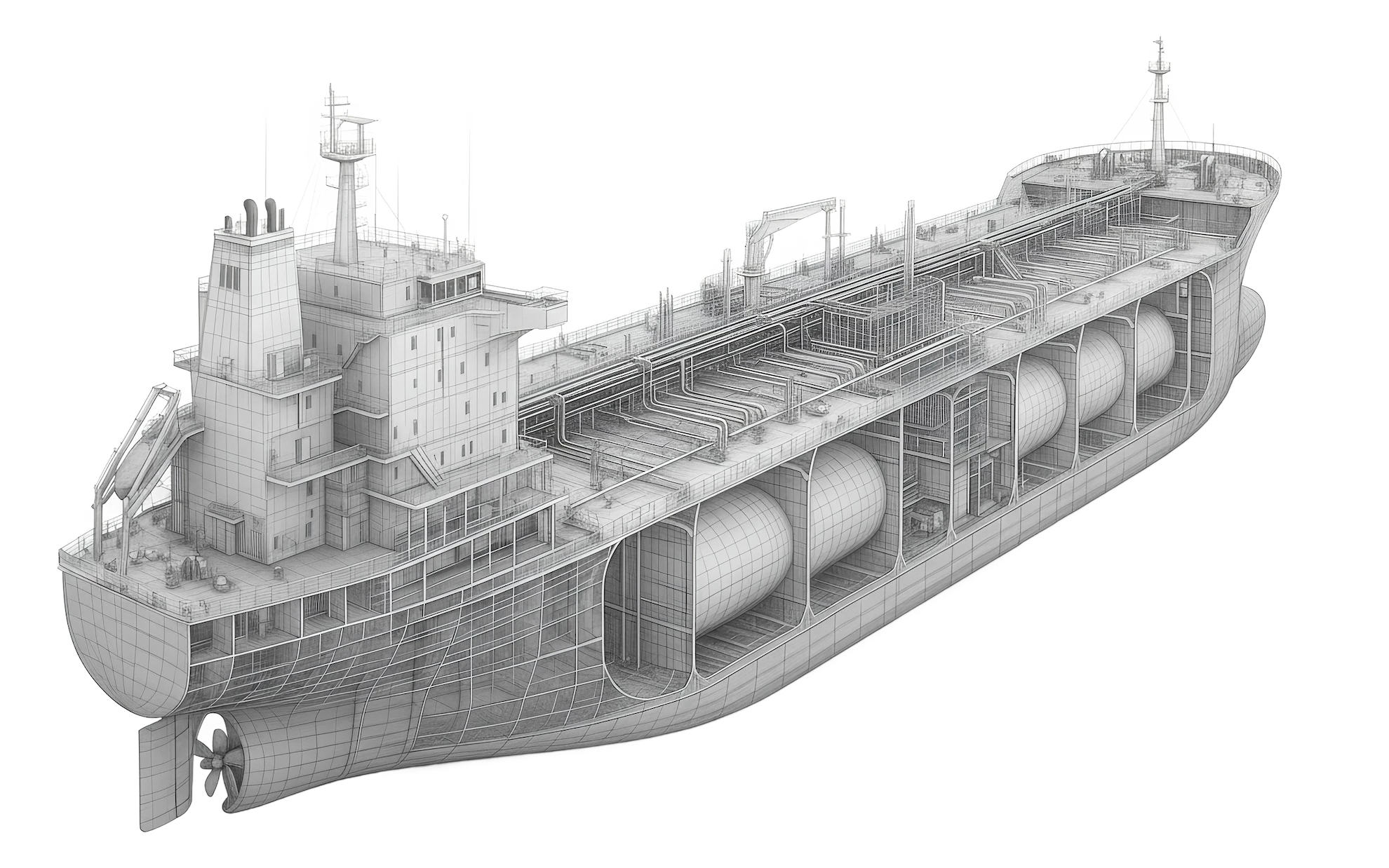

Specialized Survey Services

Anticipate Issues.

Act Before They Escalate.

Onboard SurveysHAT Analytics provides expert onboard surveys focused on vibration analysis, structural integrity, and comfort-level evaluation.

Troubleshooting ServicesThese services support troubleshooting, commissioning, and performance assessment,giving operators clear insights when deeper investigation is needed.

Failure InvestigationsRoot-cause analysis of machinery failures, supported by advanced diagnostics and historical data trends, delivering actionable recommendations.

Smart Vessel Monitoring for Peak Reliability